|

|||

|

|

|||

|

Page Title:

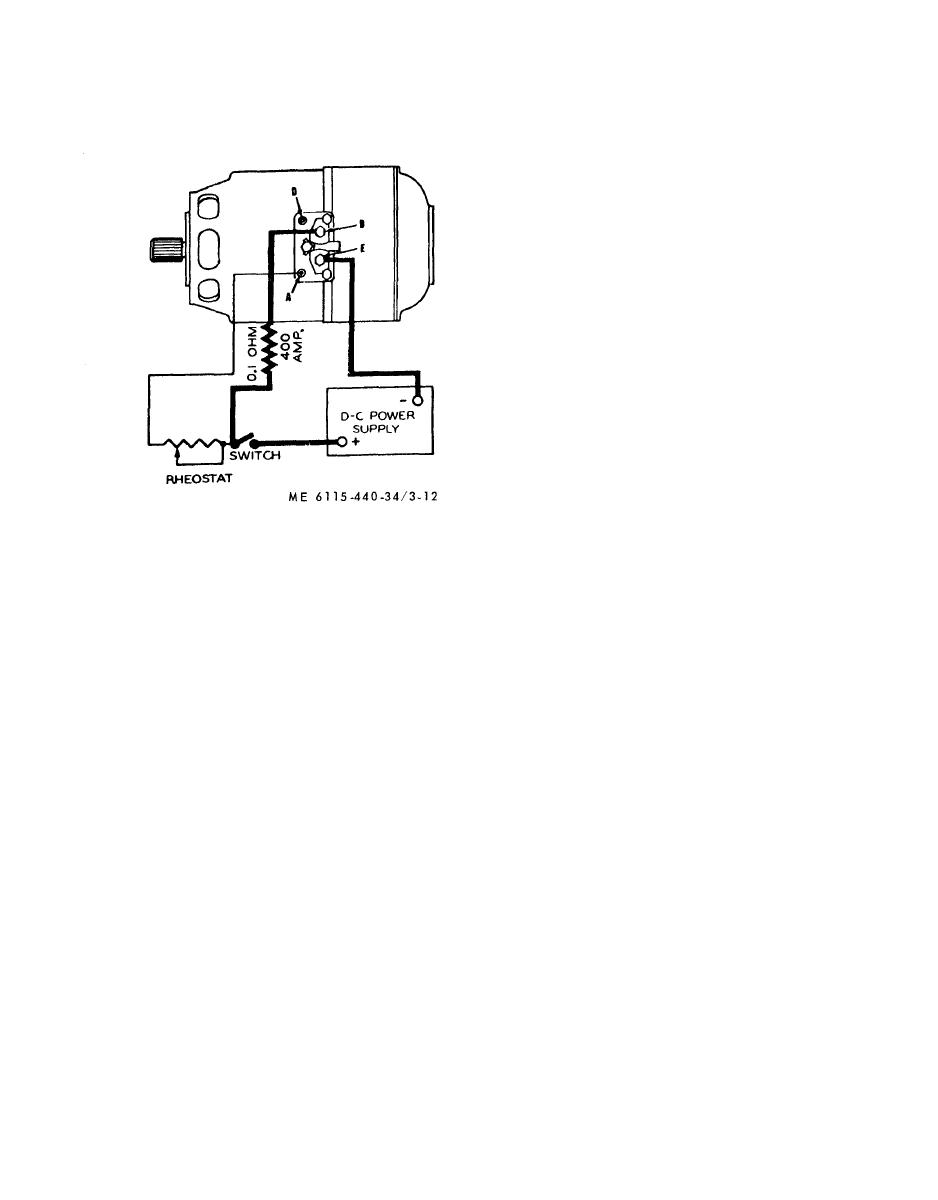

Figure 3-12. Electrical connection for running-in brushes |

|

||

| ||||||||||

|

|

NOTE

NOTE

Instead of running the generator as a motor,

Record field current, frame temperature,

commutation, a n d generator speed as ap-

brush run-in may be accomplished by using a

plicable during each test procedure.

test stand to drive the generator.

(2) Without

operational warm-up, operate

(7) Remove all carbon dust with filtered,

generator with self excitation at 8000 rpm, 30 volts

compressed air.

and no load. Shunt field current shall not be less

than 0.81 amperes. Commutation must be black.

(3) With regulator connected to generator,

operate at 6500 rpm, 30 volts, and 300 amperes

until frame temperatures show no more than 2.0F.

(1.1C) rise in five minutes. Commutation should

not be worse than pin points along the edges of

brushes. The paralleling voltage between terminals

" D " and "E" must be within limits shown on

calibration chart (fig. 3-14). Frame temperature

must not exceed the air inlet temperature by more

t h a n 230F (110C).

(4) Operate at 5000 rpm, 30 volts, 300 am-

p e r e s for demonstrating ability to operate at

minimum speed for regulation. Shunt field current

shall not exceed 8.0 amperes. Commutation shall

be no worse than pin points along the edges of

brushes.

( 5 ) Operate at 6500 rpm (revolutions per

minute), 30 volts, and vary load from 0 to 300

amperes in increments of 100 amperes to check for

compounding. The field current must increase in

Figure 3-12. Electrical connection

load:

for running-in brushes.

(6) Reduce speed to approximately 4500 rpm.

3-16. Starter-Generator Test Procedures

operate no load and open field until frame tem-

a. General. After brushes have been properly

perature is 140F. (60C) or less. Substitute a

seated and run-in, the generator should be mounted

resistance of 1.25 ohms for regulator in the field

on a test stand having sufficient capacity to handle

circuit and adjust speed to produce 26 volts and

a 300 ampere unit. T h e test stand should be

300 amperes. Operate until speed is not over 4500

equipped with a variable drive capable of attaining

rpm with frame temperature stabilized or showing

generator speeds up to 10,000 rpm.

no more than 2.0F. (1.1C) rise in five minutes.

b. Test Equipment Required (fig. 3-13).

Commutation should not be worse than pin points

(1) The variable drive, or prime mover, for

along edges of brushes.

operating the generator should have a rating of at

( 7 ) Reconnect regulator and observe con-

least 30 horse power and a maximum speed in

nutation at 30 volts, zero amperes, 200 amperes

excess of 10,000 rpm.

and 300 amperes at speeds of 5000 and 6500 rpm.

(2) A direct current voltmeter (0 to 30 volts)

Record the worse condition of commutation and

must be available for measuring terminals voltage.

the speed at which it occurs. Commutation must

(3) A direct current ammeter (0 to 300 am-

not exceed pin points along the brush edges.

peres) must be available for measuring generator

(8) Operate at 8000 rpm, 30 volts and 300

output.

amperes. Commutation must not exceed pin points

(4) A direct current ammeter (0 to 10 am-

along the brush edges.

peres) must be available for measuring generator

(9) Remove generator from test stand and test

field current.

all circuits to ground with 200 volts A. C. rms, 60

c. Performance Tests. Performance tests shall be

cycle for a period of one minute. There shall be no

with the following

c o n d u c t e d i n accordance

grounds in any circuit.

paragraphs after brushes have been seated 100

(10) Set up a dial indicator gage on generator

percent in direction of rotation and at least 90

frame and check the commutator for eccentricity by

percent in the axial direction.

rotating the armature slowly by hand. The total

(1) Mount generator on test stand and make

indicated run-out must not exceed 0.001 inch and

connections to voltage regulator and reverse current

the bar to bar change must not exceed 0.0002 inch.

r e l a y in accordance with figure 3-13. Attach

c. Installation. Install the starter-generator (para

thermocouple to generator frame.

2-8).

3-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |