|

|||

|

|

|||

|

Page Title:

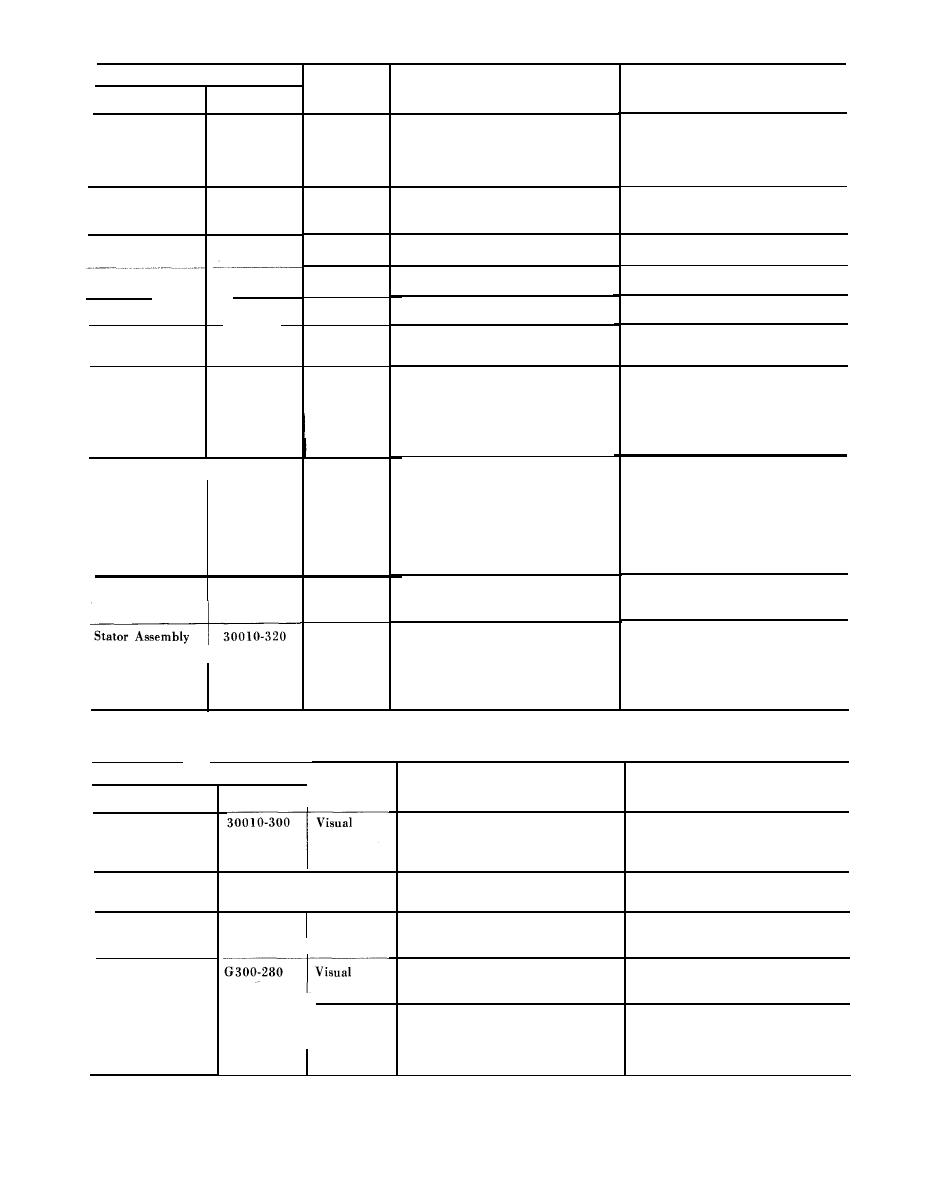

Table 3-2. Table of inspection for Parts Normall Replaced at Overhaul |

|

||

| ||||||||||

|

|

Table 3-2. Table of inspection for Parts Normall Replaced at Overhaul

Part identification

Type

of

Acceptability

Inspection

inspection

remarks

procedure

Number

Names

Brush

30010-1026

Visual

Check for cracks, chipped edges,

Replace for any of these conditions

loose or frayed wire. Lateral wear

groove in edge of brush is minimum

worn length.

Ball Bearing

Replace if defective

Visual

Inspect for binding or excessive

JH203-35

looseness

Insulation Plate

G300-199

Visual

Check for cracks

Replace for this condition

Insulating Tube

05-631120

Visual

Check for cracks

Replace for this condition

Insulating Washer 0 5 - 3 7 4 0 3 6

Visual

Check for cracks

Replace for this condition

Brush Spring

30010-1039

Visual

Check tension

Replace if not between 45 and 54

ounces

Mechanical

Replace if not within limits

Dampener Spring

G26-138

Inspect for binding or excessive

length approximately 0.468 inches.

Test that force required to com-

press spring to 0.375 inches is 34-

38 pounds

Armature Assembly 30010-1020

I n s p e c t commutator for pitting

Visual and

Replace armature if commutator is

worn below a minimum diameter of

Electrical

caused by electrical failure. Burned

adjacent bars indicate either open

3.187 inches. Replace if electrical

tests indicate a shorted, open

or shorted circuits in windings. A

circuited or grounded condition.

complete electrical test should be

performed before reconditioning

commutator

Dimensional

Replace if diameter is below this limit

Check bearing Journal diameters-

minimum 1.1810 in.

Visual and

Inspect for damage to coils, loose pole

Replace if coils are damaged whether

electrical

shoes and electrically as outlined in

visually or electrically. (Restake

paragraph 3-14d (2). Pole shoes

a t t a c h i n g screws if they are

can be tightened by turning at-

tightened),

taching screws clockwise

Table 3-3. Table of inspection

Type

Part identification

Acceptability

of

Inspection

inspection

procedure

Number

remarks

Names

Replace for any of these conditions

Check for cracks, warpage and

Bearing and

damaged screw threads in brush

Brush holder

holder

Replace if diameter exceeds this limit

Check bearing bore diameter

Support Assembly

Dimensional

maximum 2.4409 inches

Check for cracks and warpage

Replace for either condition.

Dampener Pressure 30010-1031

Visual

Plate

Replace for any of these conditions

Dampener Friction

Inspect for damaged splines also

cracks and warpage

Plate

Replace for any of these conditions.

Shaft

30010-1029

Visual and

Inspect for damaged splines warpage

Mechanical

and damaged threads. Inspect also

for hidden cracks by elec-

tromagnetic process.

3-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |