|

|||

|

|

|||

|

Page Title:

CHAPTER 2 D I R E C T SUPPORT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

CHAPTER 2

D I R E C T SUPPORT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

2-3. Maintenance Repair Parts

2-1. Tools and Equipment

Tools, equipment, and repair parts issued with or

Repair parts a n d e q u i p m e n t a r e listed and

authorized for the generator set are listed in the

illustrated in the repair parts and special tools list

basic issue items list, TM 5-6115-440-10.

covering d i r e c t s u p p o r t a n d g e n e r a l support

maintenance for this equipment in TM 5-6115-

2 - 2 . Special Tools and Equipment

440-24P

No special tools or equipment are required for

performing maintenance on the generator set.

Section Il. TROUBLESHOOTING

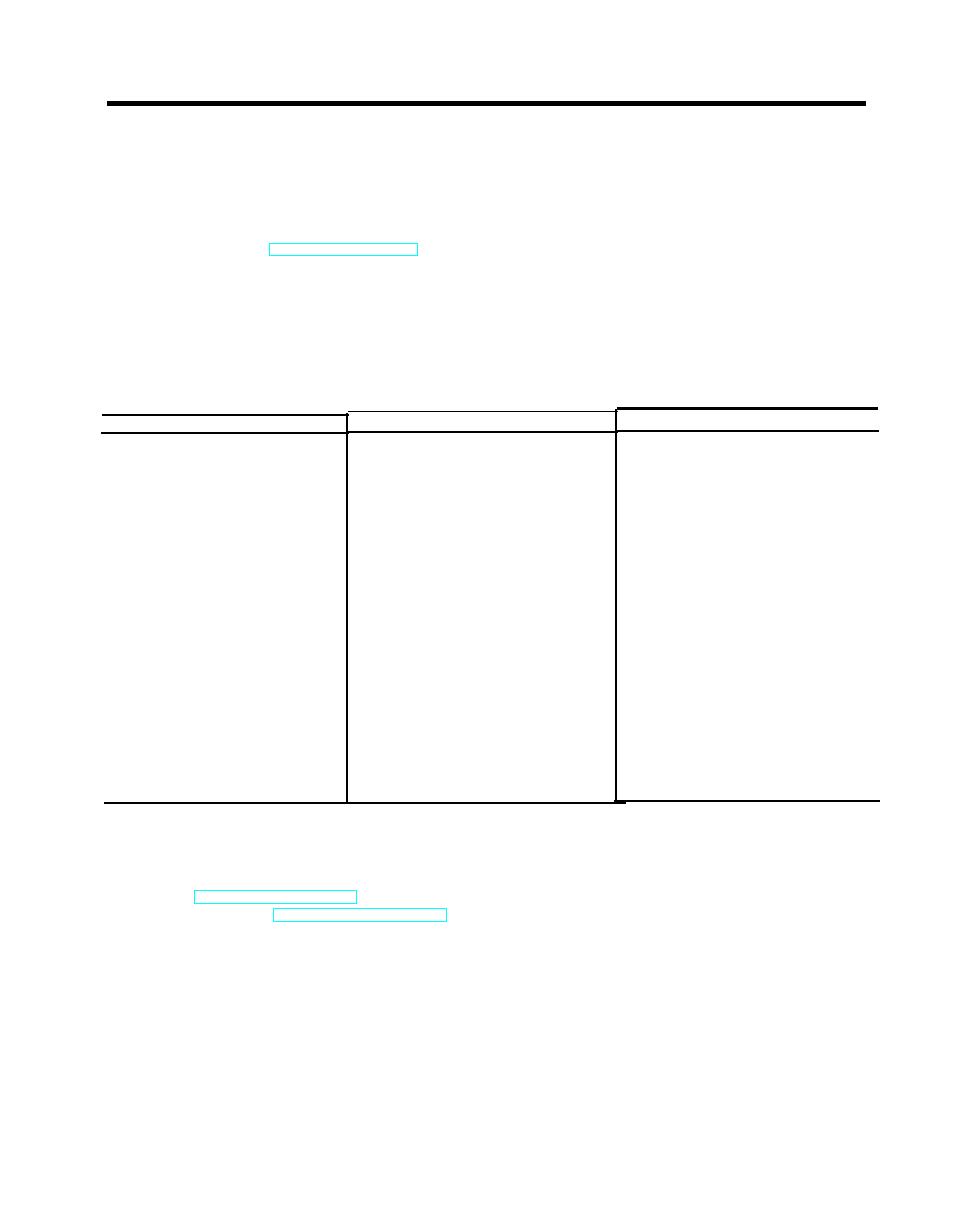

Table 2-1. Troubleshooting

Probable cause

Corrective action

Malfunction

1. Engine fails to start or starts

a. Magneto switch wiring defective

a . Check wiring and correct as

with difficulty

necessary (para 3-7).

b. Magneto

defective

b. Disassemble and replace defective

parts (para 3-13).

c. Starter generator defective

c. Disassemble and replace defective

parts (para 3-14).

2. Engine lacks power

a. Piston rings worn

a. Replace piston rings (para 3-23).

c. If cylinder are worn more than

c. Cylinders worn or scored

0.005 inch oversize, regrind and

fit with oversize pistons and

piston rings (para 3-24).

Disassemble and clean engine

Excessive carbon deposits

3. Engine overheats

components.

4. Engine knocks

a. Clean cylinder heads (para 2-6).

a. Carbon or lead deposits

b. Disassemble and correct trouble

b. Loose or defective connecting

rod shell bearing

(para 3-23).

c. Disassemble and correct trouble

c. Worn or loose piston pin

(para 3-23).

d. Replace valve spring (para 3-28).

d. Valve springs weak or broken

a. Disassemble and replace defective

5. Generator output erratic

a. Voltage regulator defective

parts (para 3-2).

b. Generator defective

b. Disassemble and replace defective

parts (para 3-6).

Section Ill. GENERAL MAINTENANCE

2-4. General

2-6. General Cleaning and Inspection Methods

a. Cleaning.

(Refer to TM 5-6115-440-10 for analysis of

operation). R e f e r t o T M 5 - 6 1 1 5 - 4 4 0 - 2 0 f o r

(1) Clean all parts in an approved cleaning

organizational maintenance instructions.

solvent (eg. FED-P-D-680).

(2) Clean surface and install new gaskets.

2 - 5 . Wiring Harness

b. Inspection.

The electrical circuits in the generator set are

( 1 ) Inspect all parts before installing for

completed by individual wire leads or by leads

cracks, wear, rust or corrosion, deterioration of

laced or enclosed to form a wiring harness. When

electrical wiring or any type damage.

testing, repairing or replacing the individual wires

( 2 ) Inspect all hardware for damage, rust

or harness refer to the wiring diagram (fig. 1-1 and

breaks and damaged threads.

1-2).

2-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |