|

|||

|

|

|||

|

Page Title:

CHAPTER 8 ERECTION INSTRUCTIONS FOR THE 10,000-BARREL CAPACITY TANK |

|

||

| ||||||||||

|

|

TM 5-5430-209-12

CHAPTER 8

ERECTION INSTRUCTIONS FOR

THE 10,000-BARREL CAPACITY TANK

Section I. ASSEMBLY AND INSTALLATION OF TANK BOTTOM

8-1.

Center Support Base

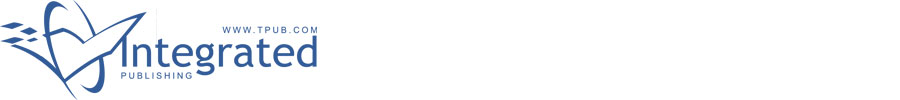

a. General. The center support base consists of a

short, tubular, support column mounted on a circular,

flat, steel plate. The support column is held in position

on the steel plate by radially extended, vertically

mounted and welded, steel gussets. The two halves of

the tank bottom adapter plate are bolted to the center

support base.

b. Installation.

(1) Drive all grade stakes below the surface

of the foundation. Backfill and tamp the resulting hole.

(2) Locate center support base blocking (2,

1.

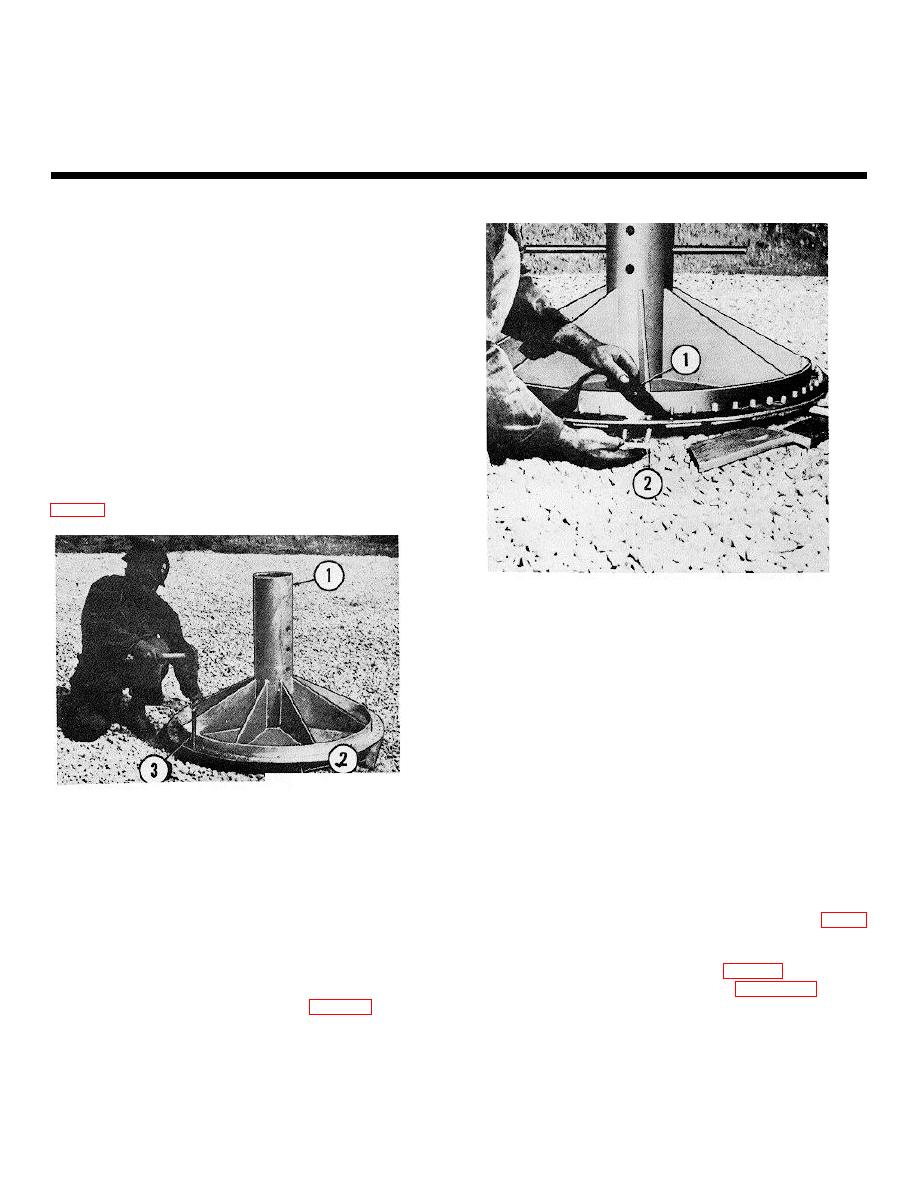

STRIP GASKET

2.

TWO-BOLT HOLE CHANNEL

ME 5430-209-12/8-2

Figure 8-2. Installing channels, bolts, and gaskets

on the center support base.

(5) Insert two l/2-by 112-inch bolts in the 2-

bolt hole channel (2).

CAUTION

1.

CENTER SUPPORT BAE

To prevent damage to the gasket, do

1.

CENTER SUPPORT BASE

not use a sharp-edged tool or pipe to

2.

BLOCKING

force the gasket over the bolts. Use a

3.

DRIFT PIN

well-rounded, smoothmouth tool.

ME 5430-209-12/8-1

Figure 8-1. Center support base.

(6) Insert the channel assembly through

center support base plate and gasket as shown in figure

8-2.

(3) Position center support base (1) over the

center grade stake. Make sure blocking (2) does not

(7) Remove blocking (2. fig. 8-1) and insert

block the entrance to the boltholes.

bolt retaining boards as shown on figure 8-3. These

boards will prevent movement of bolts when center

(4) Place strip gaskets (1, fig. 8-2) around

adapter plate is installed.

bolt circle of center support base. Where there is a

break in the gasket, overlap the joint two boltholes.

(8) Apply sealing compound

to

gasket

Make a beveled cut squarely across the second bolthole

overlap joints to insure a tight connection.

in the gasket. This will insure a smooth joint where the

gasket overlaps.

8-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |