|

|||

|

|

|||

|

Page Title:

Section II. ASSEMBLY AND INSTALLATION OF SIDE STAVES |

|

||

| ||||||||||

|

|

TM 5-5430-209-12

Section II. ASSEMBLY AND INSTALLATION OF SIDE STAVES

6-8. Assembly of Side Staves

a. General. This is a single ring tank. Place all

center support ladder components and manhole dome

on the bottom before laying staves around the perimeter

of the tank foundation. This is to avoid having to lift

them over the tops of the staves later. Top and bottom

flanged edges of staves are called chimes; side edges

are called vertical seams. The staves have two rows of

bolt holes in each seam.

NOTE

Stave assemblies for petroleum and water

storage tanks are all the same except for special

fittings.

b. Layout of Staves. Five special and 15 plain

1.

STRIP GASKET

staves make up the ring.

2.

CHIME

(1) Place staves with opening and pipeline

3.

STAVE JOINT CHANNEL

connections in proper position.

4.

BOLT

(2) Lay remaining staves around the perimeter

5.

STAVE

of the bottom. Place staves with chimed side down for

convenience in preparing them for assembly. Staves

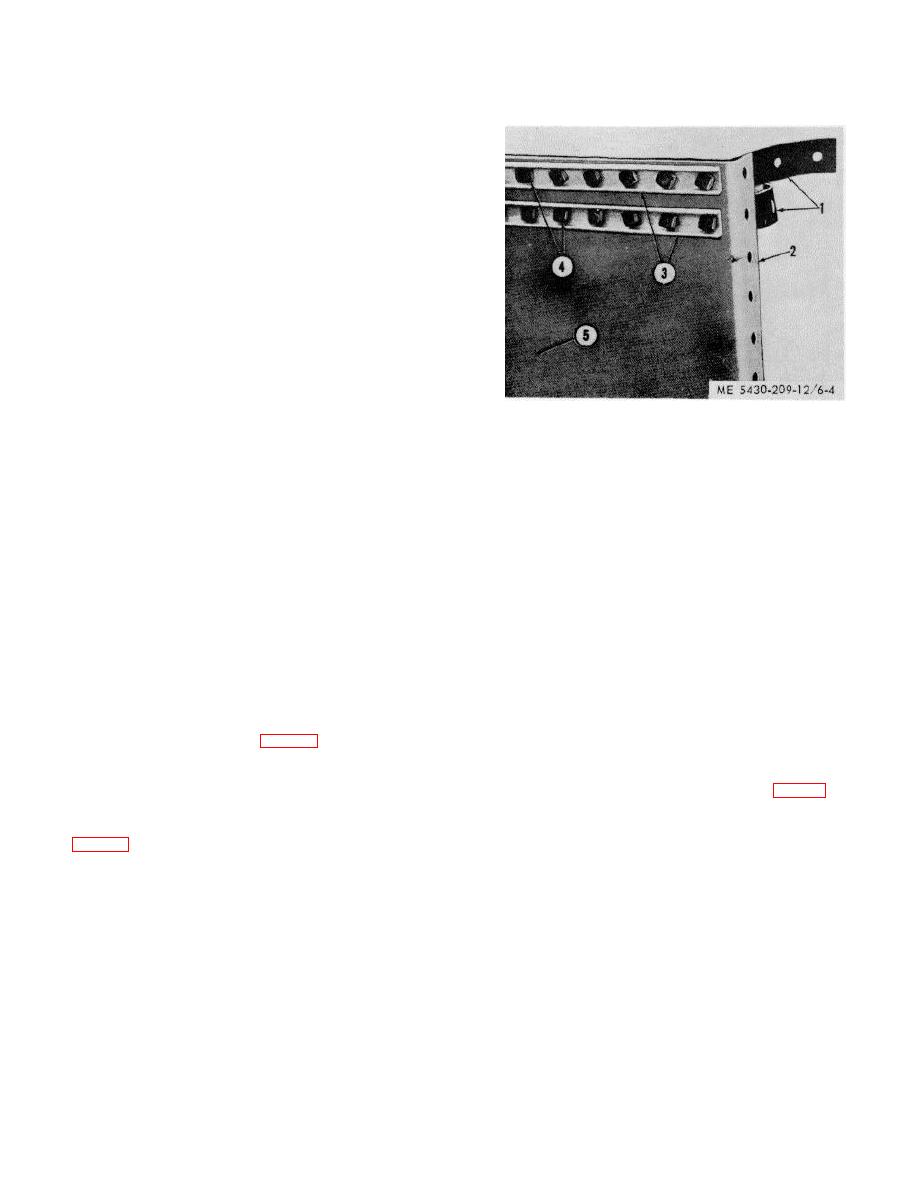

Figure 6-4. Dressed vertical seam of stave.

are laid out so each straddles a radial seam of the

bottom when installed.

(3) Place channel (3) on inside of stave (5) over

each row of boltholes.

NOTE

(4) Insert bolts (4) through stave joint channels

Staves have an offset at top and bottom. The

(3), stave (5), and gaskets (1), from the inside. Omit

top is determined by looking at the staves in a

one bolt (4) in each row of boltholes about 10 inches

vertical position from the outside. In proper

from bottom of stave and other bolts at about 2-foot

position, offsets are at the lower left and upper

intervals, so that drift-pins can be inserted to aline

left corner.

staves with one another before bolting them together.

d. Preparing Outer Edge of Tank Bottom. As no

c. Dressing Staves.

channels are used with the bolts inserted through the

(1) Each end of the chime at the offset and plain

chime (outer edge) of the bottom, it must be raised to

section must be slightly bent for ease in installing. End

provide clearance to insert and tighten the bolts for

of the chimes at the offsets (1, fig. 3-8) must be bent

installation of the staves.

inward (towards each other). End of the plain chimes

(1) Raise the chime and block it up with short

(2) are bent outward (away from each other). Bends are

lengths of 3 by 3 or 4 by 4 inch timbers (1, fig. 6-5) at

made with a few sharp blows from a hammer.

equally spaced intervals around the perimeter of the

(2) Along the right seam of each stave, as it will

bottom. Set the inner end of the blocking about 6

be put in place with the chimes out, place strip gasket

inches in from the outer edge of the chime.

(1, fig. 6-4) on the outside at each row of boltholes.

Gasket material comes in rolls and is cut to proper

length for each stave. Cut gasket material so that it

covers and projects two boltholes past the top and

bottom chimes (2).

6-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |