|

|||

|

|

|||

|

Page Title:

Table 3-1. Operator's Preventive Maintenance Checks and Services |

|

||

| ||||||||||

|

|

TM 5-5420-205-14

Table 3-1. Operator's Preventive Maintenance Checks and Services.

B-Before operation

D-During operation

A-After operation

Time required:

Time required:

Interval

Work

and

Time

Seq. No.

ITEM TO BE INSPECTED

(M / H)

B

D

A

PROCEDURE

NOTE

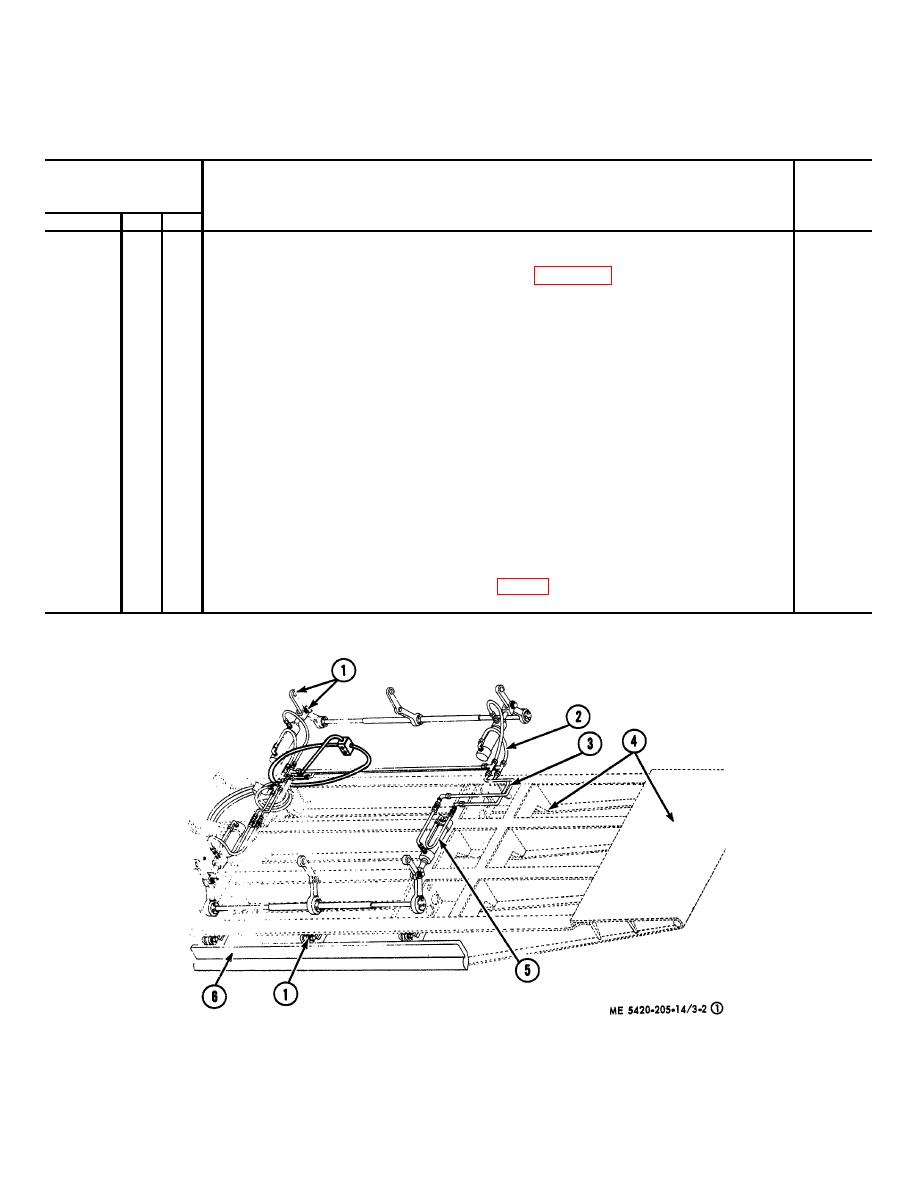

Figure item no. follows item to be inspected. Figure 3-2(1) thru (3) illustrates

for models 2271 and 2272.

PIVOT POINTS (ITEM 1)

0.2

Lubricate pivot points after each amphibious operation.

2

HOSES AND FITTINGS (ITEM 2)

0.3

Inspect hoses and fittings for cracks and leaks. Tighten loose or leaking fittings.

3

TUBING AND FITTINGS (ITEM 3)

0.3

Inspect tubing and fittings for cracks and leaks. Tighten loose or leaking fittings.

4

FRAME ASSEMBLY (ITEM 4)

0.4

Clean after each amphibious operation.

5

HYDRAULIC CYLINDERS (ITEM 5)

0.1

Inspect for leaks.

6

CURBING (ITEM 6

0.1

Clean after each amphibious operation.

7

LOCKING PINS AND GUIDES (ITEM 7)

0.2

Inspect, clean and lubricate after each amphibious operation.

8

ROTATION ASSEMBLY

0.2

Lubricate the superstructure spline (12, fig. 3-1(2)) with GAA automotive and ar-

tillery type grease. (See current LO 5-5420-205-15).

RAMP, SUPERSTRUCTURE

Figure 3-2. Preventive maintenance services, ramp, superstructure,

models 2195-1 and 2195-2 (sheet 1 of 3).

3-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |