|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

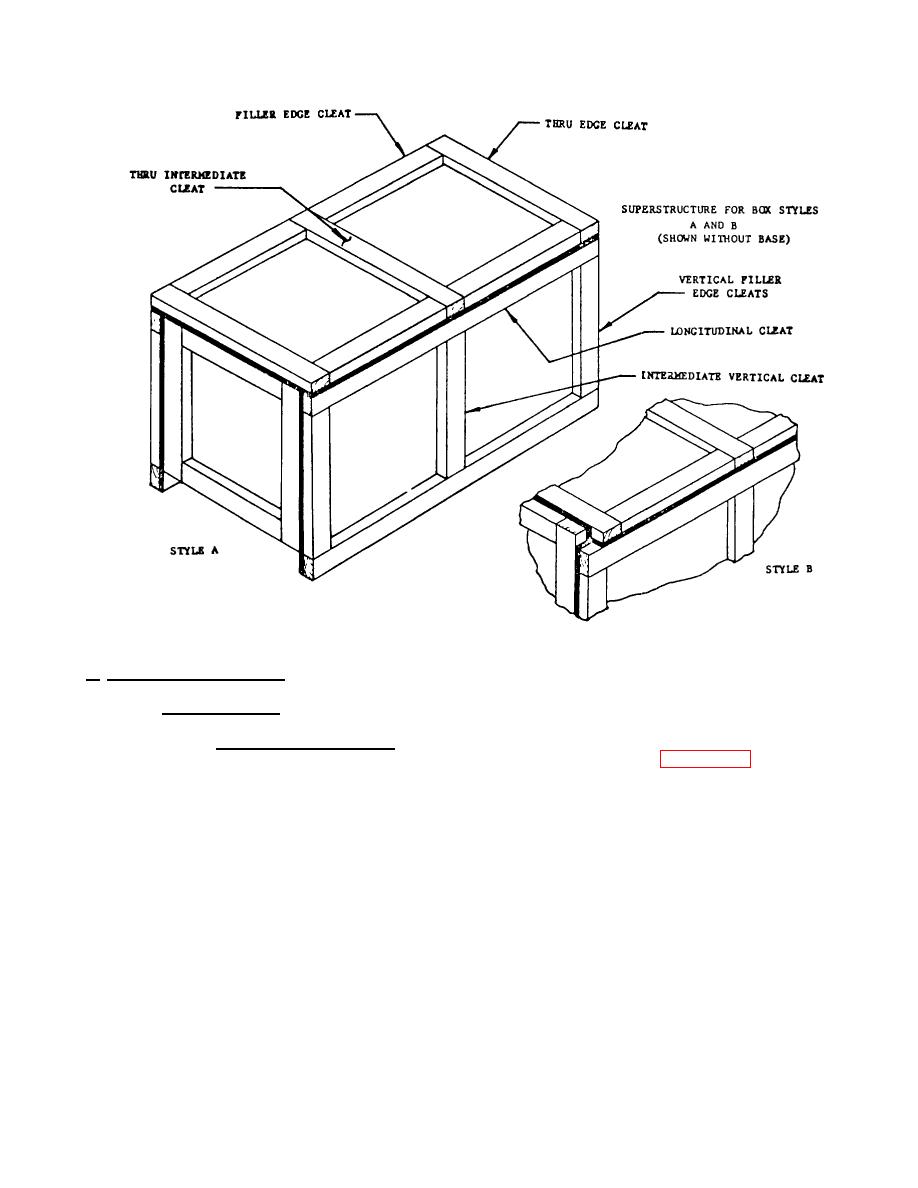

TM 43-0156

Figure D-2-2. Superstructure (style B).

b. Fabrication Requirements.

(1)

Base Fabrication.

(a)

Plywood Flooring to Skids. Plywood may be the full length and width of the container base, or it

may be a centrally located square piece with each side equal to the base width, figure D-2-3. Arrange plywood

flooring so that the grain direction of face plies is perpendicular to skid length. If more than one plywood panel

is used, leave one-fourth of an inch between panels for drainage. Nail plywood to skids according to figure D-2-

4. Make lateral edges of all plywood flooring flush with the outer edges of the outside skids. When plywood

flooring is full length of the base, place end headers and load-bearing floor members on top of plywood and bolt

to skids. Drill a 1/2-inch diameter drainage hole in each corner of full length plywood bases. Place an

additional drainage hole along the sides of the base for each 3 feet of inside length. When load-bearing floor

members are placed over plywood panels, drill at least one drainage hole on each side of the base between the

load-bearing floor members.

D-2-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |