|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.42

full unit loads, without any measurable increase in the

size of the unit load due to dunnage. Double-faced

corrugated fiberboard, thin plywood, plain fiberboard,

heavy wrapping paper, or similar materials may be used

as horizontal dunnage. The type of horizontal dunnage

to be used will depend upon the weight, shape, and

cutting qualities of the item to be palletized.

d. Horizontal binder block dunnage. Another type

of horizontal dunnage used for lateral binding of

palletized loads is binder block dunnage. This dunnage

consists of short lengths of dunnage lumber, cut to any

desired length, with short pieces of blocking secured to

each end. This dunnage is particularly adapted to the

storage of such items as soil pipe, lengths of large pipe,

or similar items which require blocking to prevent rolling

(fig 476). Use of this type binder facilitates the removal

of one or more layers of pipe from the pallet or stack at

any time by use of the fork truck. Also, it results in safe

unit loads and permits high stacking of this type of item.

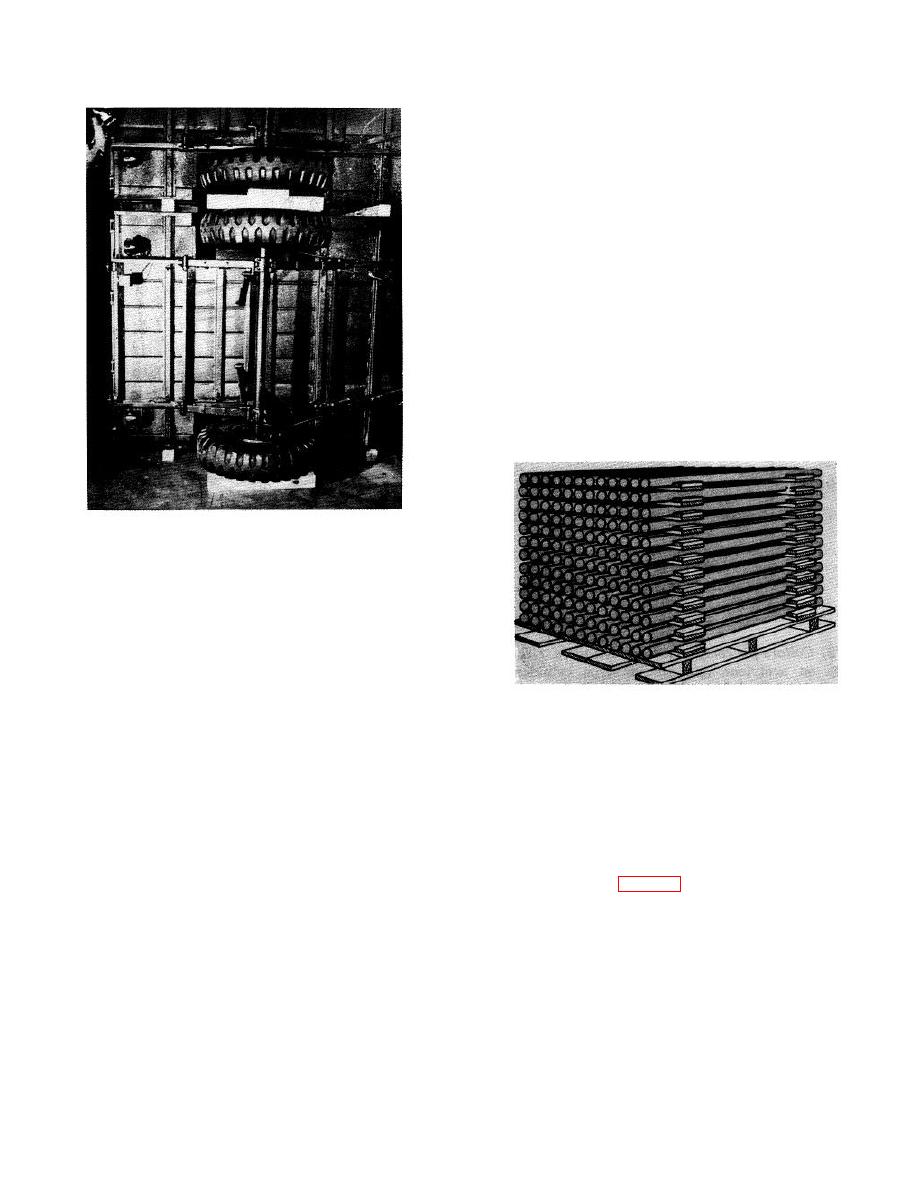

Figure 4-75. Dunnage used in the storage of

trailers.

b. Vertical dunnage. Vertical dunnage is lumber

cut slightly shorter than the overall height of the load.

When placed the same distance around the edge of the

load or between containers in a vertical position, vertical

dunnage stabilizes the load and prevents crushing of the

containers by absorbing that part of the load which is in

excess of the strength of the container. Also, pieces

Figure 4-76. Binder block dunnage used in the

may be joined at right angles, placed at the four corners

storage of pipe.

of the load, and held in position by strapping. The

proper length of vertical dunnage is determined by the

height of the pallet load. The friction of the loads upon

e. Collars and notched spacers.

each pallet bottom and the proper lengths of vertical

dunnage that will support the load provide the required

(1) Carboy collars. To stack glass carboys

stability for the stack.

and similarly packaged items, the superimposed weight

of the upper pallets must be supported in such a manner

c. Horizontal dunnage. Some form of horizontal

that the weight will be carried by the protective crating

dunnage must be used to build stable unit loads of

around the carboy; this can be accomplished by the use

noninterlocking items which will withstand handling, as a

of the wood collar (fig 4-77). By the use of this collar,

unit load, by mechanical equipment. Pallets often have

carboys can be stacked to permit maximum utilization of

been used for this purpose, by placing one or two

storage cube. Since all carboys are not identical in size

courses of a hard-to-stack item on a pallet and placing

or packaging, the dimensions of the collar will have to

the small unit loads into storage. In such storage, a

be determined by local requirements. However, care

stack 18 feet high may contain as many as seven to

should be taken to assure that the outer edges of the

eight pallets. This is an inefficient use of pallets and

collar rest directly above the sides of the carboy crate.

greatly reduces the quantity of stock which may be

The center member of the collar should be midway

stored in a given storage cube. By the use of horizontal

between the carboys and securely fastened, as this

dunnage, stable noninterlocking items can be made into

member supports the center stringer of the upper pallet.

4-43

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |