|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

unrestrained, insufficiently restrained, or overly inflated

unit will tend to assume a round shape and will transfer

excessive pressure to a limited area of the cargo facing.

When inflating disposable pneumatic dunnage, inflate

the unit slowly until the bag has filled out; rapid inflation

has a tendency to crystallize the polyethylene liner

opposite the inflator valve.

(d) Measure the resultant void.

If

excessive void is present, deflate units. (This deflation

process is more suitable for reusable units as disposal

units do not provide rapid deflation using valve fixture.)

Reposition cargo, if practicable, or insert additional

dunnage units in the void. When dunnage units are

correctly installed, they must be deflated to the normal

shipping PSI, usually 2 to 5 pounds (three-quarters PSI

max inflation in truck trailers/containers) depending on

cargo characteristics. As mentioned above, deflation

process is slow with disposable units so excessive

pressures should not be built up.

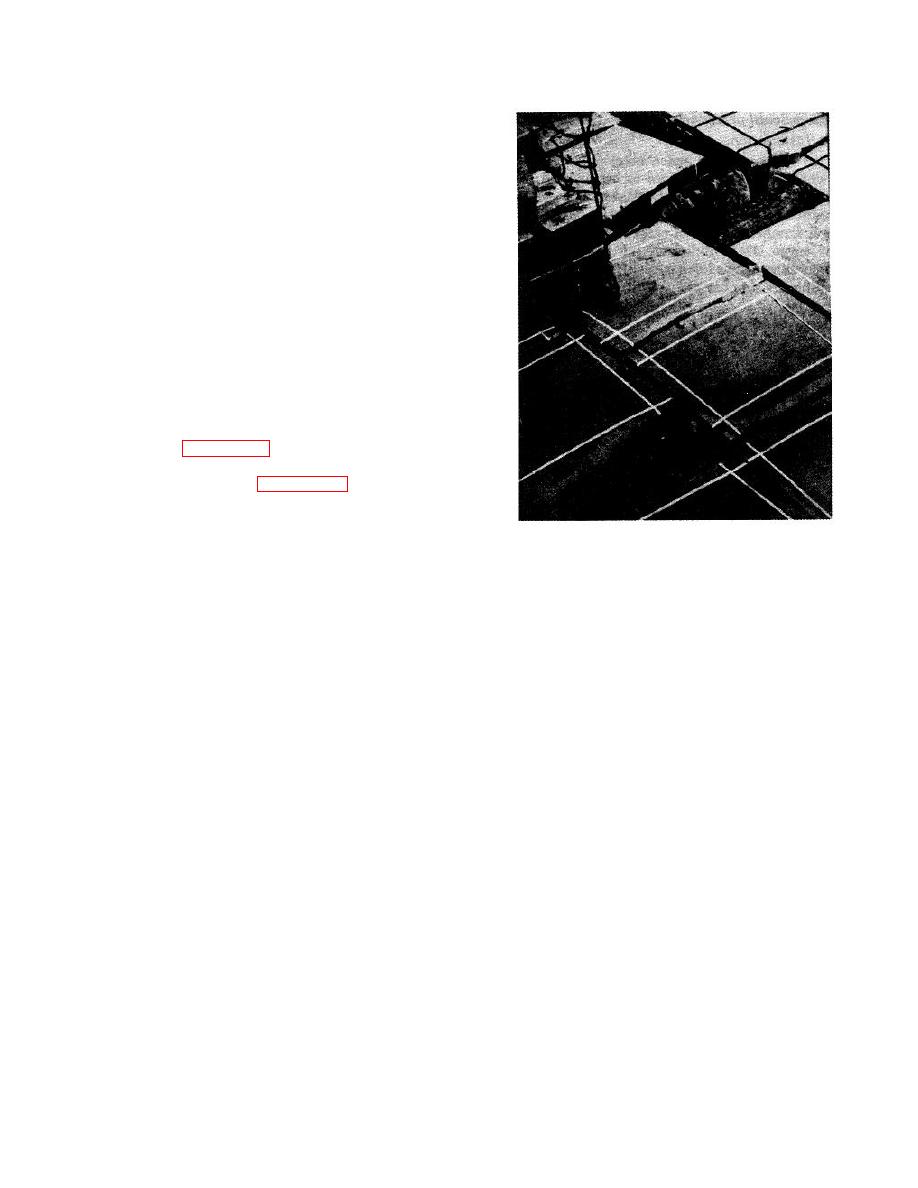

pattern in the use of disposable or reusable pneumatic

dunnage units. Observe that figure 3-53, depicting a

marine carrier application, shows multiple dunnage units

positioned side-by-side for void filling. In this area of

use (marine), this procedure has proven acceptable,

Figure 3-53. Variable sized voids occupied by

notwithstanding the comments in f(2) above.

dunnage units in storage.

(2) Removal.

(a) Cut or otherwise puncture the

disposable pneumatic dunnage units at any desirable

location on the bag and remove from conveyance.

(b) Deflate the reusable pneumatic

dunnage units by releasing the valve. Make sure that

deflation of unit(s) will not permit any unsupported cargo

to fall or shift to an unsafe position. Upon removing the

unit from conveyance, roll up toward the valve end to

force the exit of any remaining air. This should be done

immediately upon removal and the valve components

retightened to prevent valve damage or entry of foreign

material.

Units removed at destination should be

marked for inspection and repair, as appropriate.

Dunnage units should be placed in a protected storage

area if not to be immediately returned to shipper. See

b(l) above on return of units. Keep buffer boards for

further use, if practicable, upon removal from carriers.

h. Care and handling of pneumatic dunnage units.

(1) Reusable pneumatic dunnage units

should be stored in areas that are relatively cool and not

exposed to excessive sunlight. A convenient means of

storing the units is to lay them out on pallets equipped

with superstructures so as to avoid excessive

superimposed weight. Normally, not more than 25 units

3-84

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |