|

|||

|

|

|||

|

Page Title:

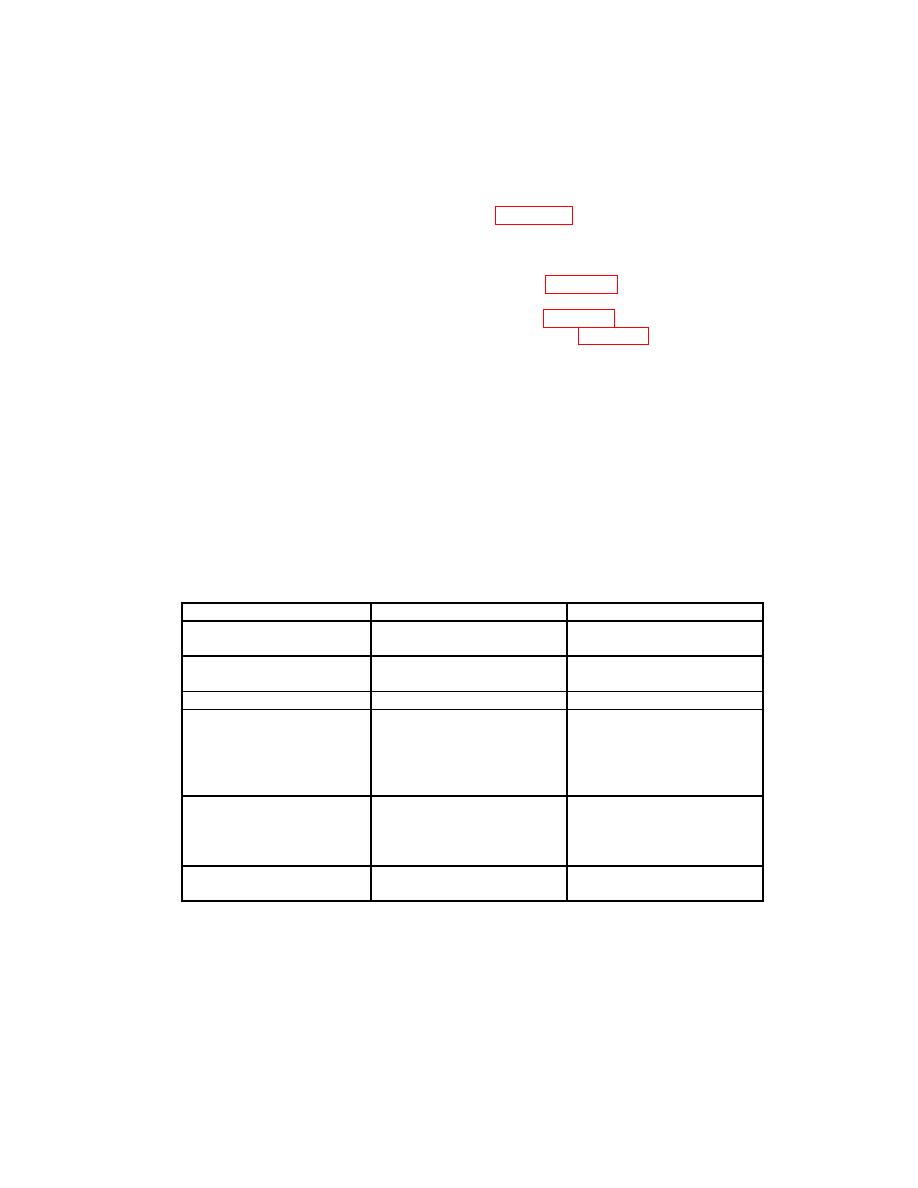

Table A-4. Wear Modes and Diagnostic Methods |

|

||

| ||||||||||

|

|

NAVAIR 17-15-50.3

TM 38-301-3

T.O. 33-1-37-3

CGTO 33-1-37-3

MH-60A/UH-60L/MH-60L/MH-60K (U.S. ARMY ONLY) (Cont.)

TAIL ROTOR GEARBOX

6. Important tail rotor gearbox wear modes are shown in Table A-4. Each wear mode is further discussed

below.

a. Gear/bearing wear - Gearbox chip lights indication should be used as the primary indicator of gear and

bearing wear. Chips present in the gearbox should be evaluated per Table A-1. Trending of chip sizes/numbers

over a time interval should be accomplished when chips are identified (either through analysis at the oil analysis

laboratory or from chip lights) but do not meet the removal criteria in Table A-1. Lab personnel may require more

frequent sampling if their trending analysis indicates the remove criteria of Table A-1 may be exceeded before the

next regularly scheduled sampling is due. The gearbox should be drained and flushed (reference paragraph 7) as

needed to remove any particles that may cause further wear if allowed to remain inside the gearbox. Indications

of iron wear metal in spectrometric analysis samples without accompanying chip lights, ferrographic, or

microscopic indications shall be tracked but shall not be cause for recommendations for removal/replacement of

the gearbox.

NOTES:

1. Indicates that the element is not the primary constituent for this component.

2. Trace amounts of C (Carbon), Mn (Manganese), P (Phosphorus), S (Sulfur),

Ni (Nickel), Cr (Chromium), Mo (Molybdenum), Zn (Zinc), Sn (Tin), Pb (Lead),

and V (Vanadium) may also be detected.

Wear Mode

Diagnostic Method

Criteria

Gear Wear.

Chip lights -or-

Table 1.

Chip size/count.

Ferrographic/microscopic.

Bearing Wear.

Chip lights -or-

Table 1.

Ferrographic/microscopic.

Chip size/count.

Housing Corrosion.

Spectrometric.

Magnesium PPM level.

Inboard Retention Plate/

Spectrometric -and-

Titanium and Aluminum

Output Gear Spline

Inboard retention plate nut

PPM levels.

Wear.

bolt torque check (per

Failure to stabilize torque

TM55-1520-237-23)

(per

TM55-1520-237-

23)

Split Cone Wear.

Spectrometric -and-

Copper and Aluminum

Inboard retention plate nut

PPM levels.

Bolt torque check (per

Failure to stabilize torque

TM55-1520-237-23)

(per TM55-1520-237-23

Pitch Control Shaft

Inspection (Phase, per

Bushing OD (per

Bushing Wear.

TM55-1520-237-PMS-2)

TM55-1520-237-PMS-2)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |