|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

NAVAIR 17-15-50.3

TM 38-301-3

T.O. 33-1-37-3

CGTO 33-1-37-3

ENGINE: J57-P-19/-29/-43/-59

AIRCRAFT: (B-52/C-135)

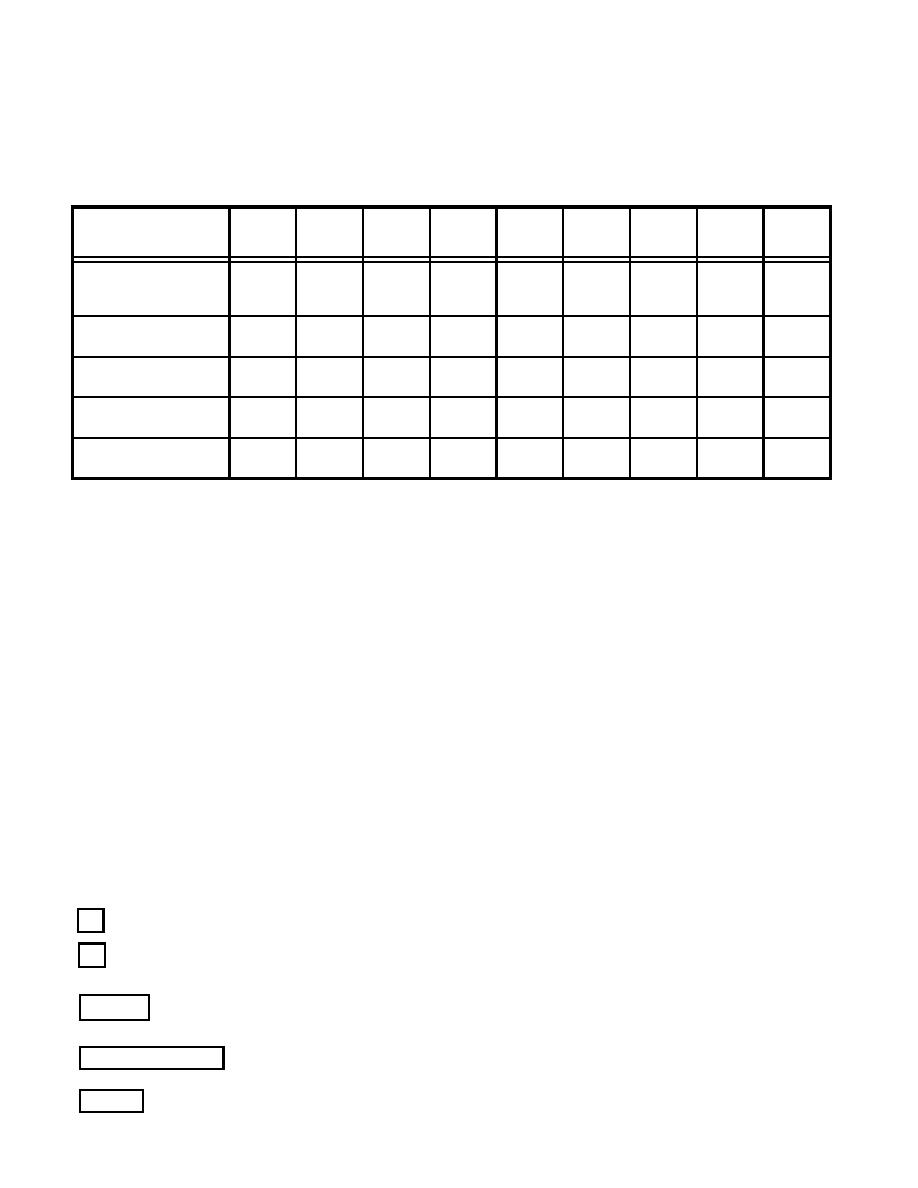

JOAP ATOMIC EMMISION ROTRODE

Fe

Ag

Al

Cr

Cu

Mg

Ni

Ti

Abnormal Trend

(PPM Increase

9

2

3

3

3

4

4

in 10 hrs)*

Normal Range

0-6

0

0-2

0

0-1

0-2

0-1

Marginal Range

7-10

1

3

1

2

3-4

2-3

High Range

11-16

2

4

2

3

5

4

Abnormal

17+

3+

5+

3+

4+

6+

5+

Average Concentration Other Elements:

Ni=1

Pb=2

Si=3

Sn-6

Mo=1

*

If the calculated PPM trend value is equal to or greater than the trend PPM value limit, the engine has an

abnormal trend.

Cu is the most significant and critical wear metal. When Cu is detected by itself in any amount, maintain close

surveillance. Increasing trends in Cu are usually indicative of problem in the Nos. 2, 4, and/or No. 5 bearing. In

cases of advanced wear, Cu may be accompanied by increases in Fe. Whenever Fe increases in combination

with an increase in Cu, for J57-43/59 engines, first remove the angle drive and inspect the top roller bearing for

cage separation, then for all engines, inspect for excessive Nos. 2, 4 and/or 5 bearing wear. Ag may also be

detected in advance bearing wear. Increases in Mg usually indicate discrepancy in accessory gearbox (OPAH).

When Mg is accompanied by an increase in Fe, the discrepancy is usually in the OPAH bearing area. When A1

increases to abnormal value or is accompanied by a small increase in Fe and, sometimes, Cu, the discrepancy

is usually with the main lube pump or scavenge pump. Increases in Cr indicate excessive wear or failure of

carbon seal. Increase in Ti indicates Nos. 1, 2, 2-1/2, and/or No. 3 bearing hub wear in J57-43 engine. Increase

in A1 by itself to abnormal values may indicate a discrepancy in the angle drive coupling. Recommend an

inspection to determine whether the angle drive coupling snap ring is out of place or bent in a manner to result in

coupling rubbing. Although Pb is not a critical element it may be found in relatively high levels. If Pb only is high

and other critical elements, i.e., iron, cooper, etc., are well within limits and Pb exceeds 50 PPM, recommend

engine be placed on code "J" (drain and flush). If the Pb levels drop below 50 PPM after the first flight, place the

engine on routine sampling intervals.

Ti

Nos. 1, 2, 2-1/2 and/or No. 3 bearing hubs (applicable to -43)

Fe

Main bearing balls/rollers, races and seals

Gearbox gears

Fe

Al

No. 6 scavenge oil pump (applicable to -43)

Gearbox oil pump (applicable to -19/-59)

Fe

Al

Ag

Cu

Nos.4, 4-1/2 and 5 scavenge oil pump

&

Si

Sn

Fe

Ag

Nos. 2-1/2 and 3 bearing cages (2-1/2 bearing applicable to -43)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |